APEC Kolath

Plot No. 38 Kunnapattu Road

Kunnapattu

Tamil Nadu 6023105

India

18th December 2026

Miss Lee, Environment and Sustainability Manager, Lucky MedTel

Dear Miss Lee,

I refer to your recent letter, in which you ask for information to assist with the environmental and social reporting LMT is endeavouring to undertake in all locations worldwide.

The rebuilding of the warehouse is nearing completion, and as you are, no doubt aware, the 3 employees found guilty of arson are imprisoned, awaiting the death penalty. APEC Kolath has been cleared of any responsibility in this matter. The allegations in the newspaper article you included are unfounded, and therefore, no charges have been brought against us.

I look forward to the visit of your Consultant Auditor. In the meantime, please find enclosed the information you requested.

Yours sincerely

Lalit Choudray

Mr Lalit Choudray

General Manager

Enc Information Requested

I N F O R M A T I O N R E Q U E S T E D

The top 6 raw materials (in terms of yearly costs) used in APEC Kolath

The manufacturing of plastic moulding and forming relies on good quality raw materials. These are now imported from China as we had a series of problems with Erfde Automotive over components supplied with non-colourfast plastics purchased locally. How our suppliers run their business (e.g. where they make their significant investments or workers’ rights) is not something we concern ourselves with and anyway we do not need to visit any of these Chinese suppliers as we purchase via an importer in Chennai. There was a rumour that the manufacturing companies in China were in trouble for employing child labour but as our contract is with the importer, we are not going to worry about this.

The manufacturing of our electronic products relies on quality minerals, usually from Africa and Asia. I am not aware of whether these are conflict minerals, but we use large and small suppliers; from foreign companies operating in developing countries (copper-gold from Indonesia) to small-scale family run concerns (minerals from Africa). Only Tantulum appears on the list of the top 6 raw materials:

- Polyvinyl chloride (PVC) is our biggest yearly cost. It is relatively cheap, but we use it in large quantities for the mouldings we make to house electronic components for our automotive customers. We are aware of some environmental and health concerns with this material.

- Polybutylene terephthalate with 30% glass fibre is the second highest yearly cost. It is purchased as resin powder and melted in the moulding process to form the casing of under bonnet electrical components. There is emerging evidence of health concerns from working with this material, but as nothing has been officially published and we tell the workers not to handle the resin powder without gloves we do not consider this a health and safety concern.

- Toluene, a solvent used for cleaning/degreasing metal inserts for our plastic mouldings and as paint thinner, is our third largest spend. We have a contract with A B Chemicals (India) Pvt Ltd. in Mumbai to deliver solvent in batch quantities every 3 months. If the workers did not leave the tanks open for the solvent to evaporate or spill so much of it, toluene would not be in our list of top 6 raw material spending.

- Paint is our fourth biggest yearly cost. Despite the high levels of volatile organic compounds in the paint we buy from A B Chemicals it is better value for money than the alternative available locally from Chennai Paints Pvt Ltd. which contains less hazardous materials.

- Tantalum is our fifth biggest yearly cost. It is an expensive raw material and is extracted from Coltan (columbite and tantalite). The refined Coltan is used as a heat-conducting mineral in capacitors and is a key component in many products we manufacture for mobile phone technology for cars. Tantalum’s unique ability to withstand extremely high temperatures makes it an ideal material for capacitors (used to store energy in the electric field between conductors in an electronic device). Our Purchasing Manager has indicated that the supplier is based in Thailand; he believes they source Tantalum from the Democratic Republic of Congo in Africa, but we have not asked for formal confirmation.

- Oil is our sixth largest yearly cost. The oil is used to lubricate the moulding and forming machines. Again, we receive the cheapest costs when we buy in large batches every 3 months from A B Chemicals.

We have not had the opportunity to visit any of these operations, or carry out any supplier audits, as they are far from Kunnapattu. However, as A B Chemicals is owned by my brother-in-law and he knows the Tantulum supplier in Thailand we get good prices which is good business for us. Contact details for the supplier of highest yearly spend.

Our highest yearly spend is with A.B. Chemicals (India) Pvt Ltd, who supply us with the solvents, paint and oil. They based in Mumbai, the address is:

A.B. Chemicals (India) pvt.

I-3A Ganesh Mandir Marg

Juinagar

Mumbai

400706

India

Recycled raw materials

2 years ago, our Purchasing Manager investigated the opportunity to use recycled Polybutylene Terephthalate with our current material supplier. He obtained a quotation for the recycled material from them and it proved to be a small amount more expensive than virgin resin. However, he believed that moving to completely recycled materials could be a problem as their supplies of an appropriate quality of recycled material may not be guaranteed. We therefore have not pursued this with our current supplier or alternative suppliers as an option for either full or mixed virgin/recycled raw materials for any of the plastic resins we purchase. In addition, our supervisors feel that recycled resins could not be substituted for virgin resins without modifications to our machinery and processes which will slow production rates and incur additional set up costs. The workers would also have to be given additional training to use the recycled materials and we don’t want to do that as they would stop working whilst being trained.

The photographs you requested – Photos of some employees as they go about their various activities at work.

Photo 1 : Directors of Erfde Auto pictured with Rinehold Gerter’s corporate helicopter outside the APEC Kolath Factory in Kunnapattu.

Photo 2. A group of migrant workers, taking packaging waste to be recycled. At APEC Kolath we recycle 10% of all packaging.

Photo 3: This is a photo taken 18 months ago of the 3 migrant workers found guilty of arson.

Photo 4: Workers waiting to leave the factory at end of shift

Photo 5: Workers moving solvents for use in production

Photo 6: Workers moving raw materials for use in plastic production

Photo 7: Rebuilding of Warehouse

Photo 8: A worker carrying out some repair work, after the recent fire

Photo 9: Factory after the fire

Photo 10: Spraying paint on plastic mouldings

Photo 11: APEC Kolath factory

Photo 12: Workers Living accommodation (Female)

Photo 13: Workers Living accommodation (male)

Photo 14: Inside the female dormitory

Photo 15: Inside the female dormitory

Photo 16: Inside the female dormitory

Photo 17: Recently refurbished male dormitory (note: we have included smaller beds for the younger workers to ensure we can accommodate more staff members)

Photo 18: Workers relaxing in their dormitory.

Photo 19: Workers relaxing in their dormitory.

Photo 20: Workers queuing to receive their wages

Health & Safety Committee

Our Health & Safety Committee meet once a year. Minutes of these meetings will be available for your Consultant to see on their visit. The members are:

| Name | Position | Nationality |

| Hans Gustafson* | Operations Director | German |

| Ron Goldstein* | Human Resources Director | American |

| Lalit Choudhary | General Manager | Indian |

| Paul Collingwood | Factory Manager | British |

| Nigel Simmons | Purchasing Manager | British |

| Charles Bradley | Sales Manager | American |

| Helmut Schmidt | Supervisor Shift 1 | German |

| VJ Singh | Supervisor Shift 2 | Indian |

| Ritter Stein | Factory Supervisor | German |

| Asraf Nural | Factory Supervisor | Indian |

| Jan Schnuurbart Mitesh Lakhani | Stock Control Supervisor Stock Control Supervisor | German Indian |

| Klaus Bonn* | Company Accountant | German |

Details of Accidents

The HR department keep injury records. Perhaps it is better if you do not report on this indicator, as the explosion claimed the lives of 4 workers, and injured 13 others. The records are also a little incomplete as not all supervisors chose to record accidents that happen on their shifts.

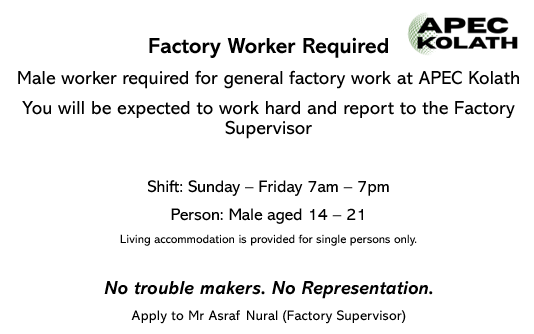

Details of employment opportunity at APEC Electronics.

We have no written employment procedure. However, our Factory Supervisor is a good judge of character when it comes to recruiting factory staff. We currently have a vacancy for a factory worker; this is the advert we have placed on the notice board. Please note that we pay approximately the Tamil Nadu minimum wage rates for all our factory workers.

Job advert

Incidents of Discrimination

Fortunately, we have not had any incidents of discrimination reported at APEC Kolath.

Leave a Reply

You must be logged in to post a comment.